Servo drives empower industrial automation: in-depth analysis of multi-scenario application solutions

In the field of industrial automation, servo drives, as core control components, play a vital role. Its high precision, fast response and stable control capabilities make it the first choice for many industrial application scenarios. This article will start from the basic principles of servo drives, deeply explore its application scenarios and specific cases in different industrial fields, and look forward to its technical challenges and development trends.

Basic principles of servo drives

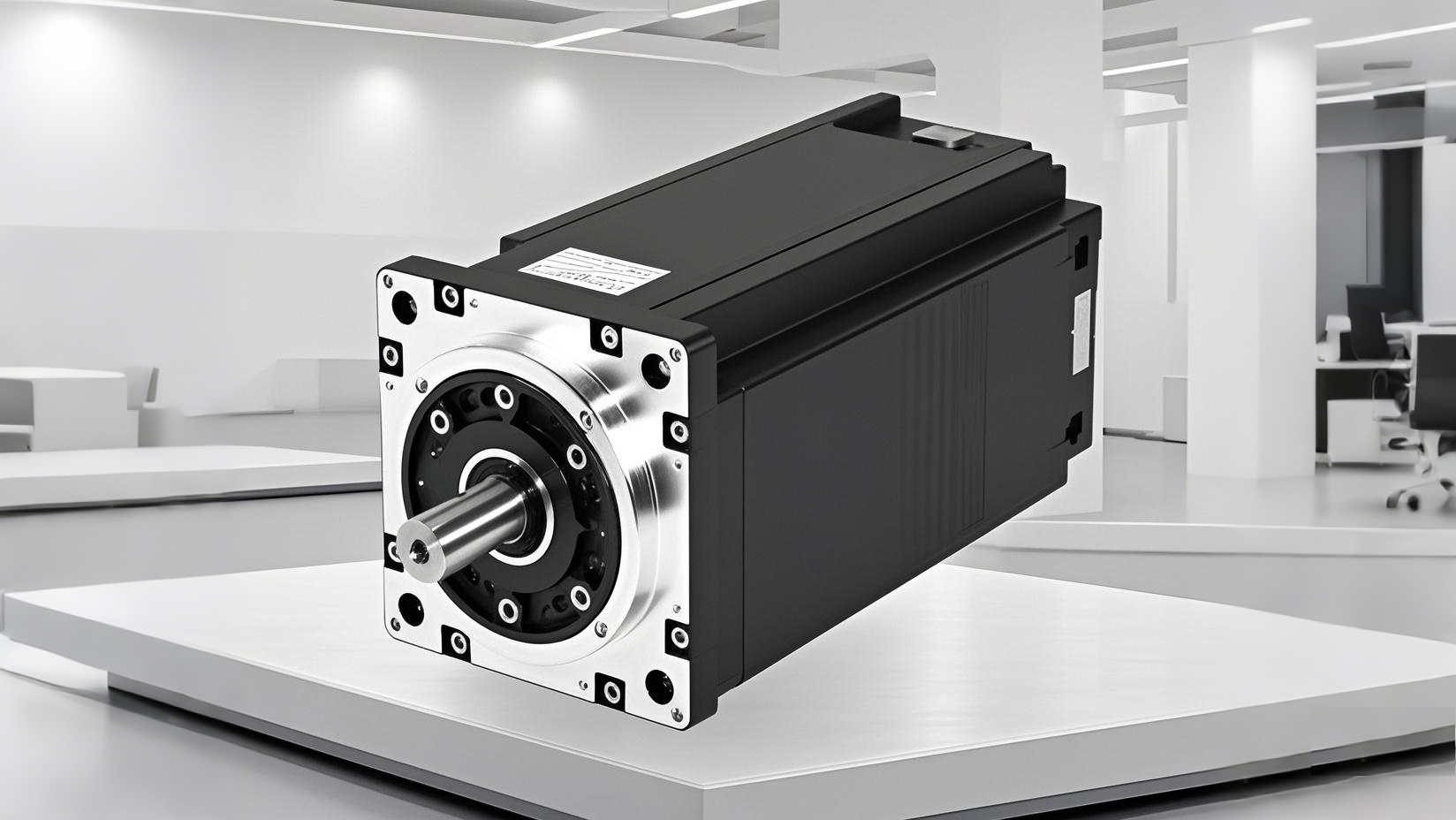

A servo drive is a device used to control and drive a servo motor. Its basic principle is to control the rotation angle and rotation speed of the motor. By receiving pulse signals from the controller, the servo drive can accurately control the movement of the motor, thereby realizing various complex industrial control tasks.

Specifically, a servo drive is usually composed of a power supply, a controller, a motor, and a sensor. The controller is the core component of the servo drive, which is responsible for receiving pulse signals from the outside and converting them into the control signals required by the motor. At the same time, the controller also monitors and adjusts the operating status of the motor to ensure the stable operation of the motor. The rotation speed and rotation angle of the motor are monitored by sensors, and the monitoring results are fed back to the controller. The controller adjusts the control signal of the motor according to the feedback signal to achieve precise motion control.

The working principle of the servo drive can be divided into three stages: control input stage, internal processing stage and output control stage. In the control input stage, the servo drive receives control signals from the outside, including pulse signals and direction signals. In the internal processing stage, the controller calculates and adjusts the control parameters of the motor according to the control signal, and monitors the running status of the motor at the same time. In the output control stage, the controller outputs the control signal according to the calculation result to control the rotation angle and rotation speed of the motor.

Industrial application scenarios

Industrial robots

In the field of industrial robots, servo drives are the key to controlling the precise movement of robot joints. Through servo drives, robots can achieve multi-axis collaborative operation and complete complex tasks such as welding, handling, and assembly. For example, in the field of automobile manufacturing, six-axis robots achieve body welding through servo drives.

CNC machine tools (CNC)

In the field of CNC machine tools, servo drives control the machine tool spindle speed, tool feed and position positioning to ensure processing accuracy.

Case: In the field of precision machining, the five-axis linkage machining center achieves high-precision machining of aircraft engine blades through servo drives. Siemens SINAMICS drive system can provide ±0.001mm machining accuracy, ensuring that the blade geometry and size meet the design requirements. In the field of metal cutting, servo spindle drive achieves high-speed cutting. For example, Mitsubishi MR-JE series drive supports a speed of 20,000rpm, which significantly improves cutting efficiency.

New energy equipment

In the field of new energy equipment, servo drives are used in the manufacturing and control systems of lithium batteries, photovoltaic and wind power equipment to improve production efficiency and energy conversion efficiency. For example, on the lithium battery production line, the winding machine uses the servo drive to align the pole pieces. In photovoltaic equipment, servo drives are used to control the high-speed positioning of photovoltaic stringing machines.

Packaging and logistics automation

In the field of packaging and logistics automation, servo drives achieve high-speed and precise control of sorting, palletizing, filling and other links to meet flexible production needs.

Case: In the field of food packaging, servo drives control the filling volume. For example, Schneider Lexium series drives achieve a filling accuracy of ±1ml to ensure product quality and consistency. In the field of express sorting, cross-belt sorters achieve fast positioning through servo drives. The L7 series drive from Leadsun Intelligent supports a response time of 0.1 seconds, significantly improving sorting efficiency.

Semiconductor and Electronic Manufacturing

In the field of semiconductor and electronic manufacturing, servo drives control the high-precision movement of equipment such as wafer handling, placement machines, and photolithography machines. For example, in the field of chip packaging, die bonders achieve precise placement of chips through servo drives.

Medical Equipment

In the field of medical equipment, servo drives are used in CT machines, surgical robots, analytical instruments, etc. to ensure smooth and vibration-free motion control.

Case: In the field of surgical robots, the da Vinci system achieves precise operation of the robotic arm through servo drives. For example, servo drives that require SIL3 safety certification ensure safety and stability during surgery. In the field of imaging equipment, MRI scanning beds achieve precise movement through servo drives. For example, ebm-papst low-noise drives avoid interference with the imaging process and ensure image clarity and accuracy.

Textile and printing machinery

In the field of textile and printing machinery, servo drives control the synchronous movement of spinning, weaving, and printing rollers to improve the quality of finished products. For example, in the field of digital printing, inkjet heads are positioned at high speed through servo drives.

Aerospace and military industry

In the field of aerospace and military industry, servo drives are used in high-reliability scenarios such as flight simulators, missile servo control, and satellite antenna positioning.

Case: In the field of wind tunnel testing, servo drives adjust the attitude of aircraft models. For example, drives that are resistant to extreme temperature changes ensure stability and reliability during testing. In the field of radar systems, servo drives enable antennas to quickly track targets. For example, military-grade servo drives support an operating temperature range of -40℃~85℃ to ensure the performance and stability of radar systems.

Technical challenges and development trends

Although servo drives are widely used in the field of industrial automation, they also face some technical challenges. For example, as the size of robots decreases, the requirements for the integration of servo drives are getting higher and higher; with the development of artificial intelligence technology, servo drives need to be more intelligent to adapt to more complex control needs; in harsh environments, the reliability and durability of servo drives are key.

In the future, servo drives will evolve towards higher integration, intelligence and greenness. For example, integrating AI adaptive control algorithms to improve the system's adaptability and control accuracy; using GaN power devices to improve energy efficiency and power density; supporting industrial communication protocols such as OPC UA over TSN to achieve connection and collaboration with other smart devices.

Conclusion

As a core component of industrial automation, servo drives play a key role in multiple industrial fields with their high precision, fast response and stable control capabilities. By continuously optimizing control algorithms, improving energy efficiency and power density, and supporting industrial communication protocols, servo drives will promote industrial automation to a higher level. In future industrial automation applications, servo drives will continue to play their advantages and provide strong support for intelligent manufacturing and industrial upgrading.